Precision Robotic Manufacturing

From Prototypes To Large Volume Automated Production

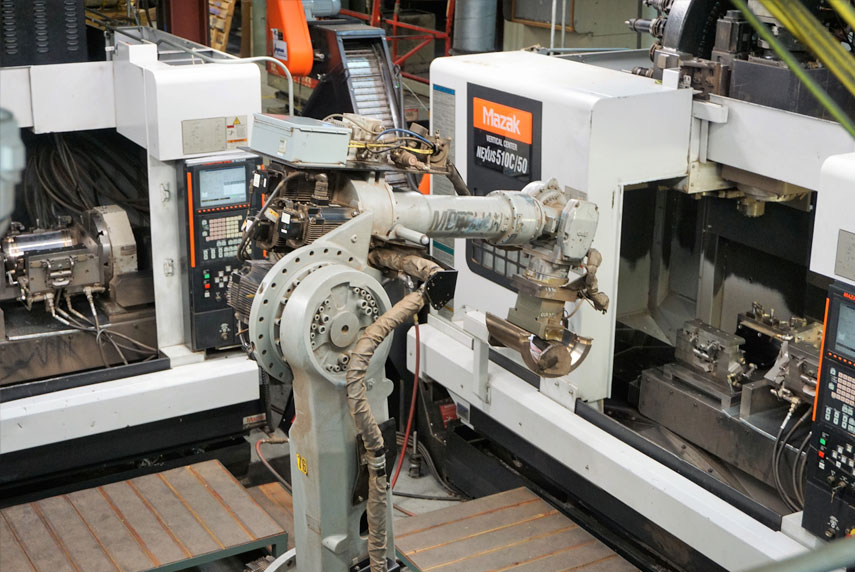

Advanced robotics requires sophisticated tooling and programming.

We use state-of-the-art robotic arms and other systems to place and remove bearings, improve the accuracy of loading and handling as well as deburring or removing sharp edges. Our investment in robotics results in quality and precision far beyond normal hand methods.

Our engineering and manufacturing innovations have become benchmarks of the industry.

Our focus on perfection optimizes the life of Magnus bearings and improves the performance of the locomotive and the efficiency of your railroad.

- We’re specialists in high-leaded bronze and centrifugal casting for superior grain structure in the bearing bronze.

- Our Statistical Process Control methods (SPC) maintain consistent metal chemistry and casting weight.

- A horizontal centrifugal casting method pioneered by Magnus safeguards the integrity of the bearings.

- Our new, improved skewed access design improves performance in the lower load zone.

- Our skilled workers deliver tighter tolerances on critical dimensions.

- State-of-the-art tooling decreases variations from part to part.

- We offer patented enhancements for today’s higher performance applications.

- At Magnus, we use advanced robotics to place and remove bearings, and pneumatic collection of bearings for re-manufacturing.