The Industry’s #1 Supplier Of Railroad Bearings Worldwide

The Premier Supplier of Bearings To The World’s Railroads

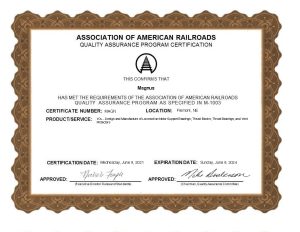

Since 1885 we’ve remained true to the spirit of stewardship and innovation that has helped us become the premier supplier of bearings to the world’s railroads. As stewards of the industry, Magnus fills a critical void in expertise and service as experienced OEM and railroad trained bearing specialists retire. Our engineering and manufacturing innovations have become benchmarks of the industry. For example, a recent Magnus patent better aligns the support bearing’s bore profile to match the axle’s journal surface when the bearing is operated in its lower load zone.

Today, Magnus proudly stands behind our pledge of stewardship to the railroad industry throughout North America and in more than 25 international locations.

Exceeding expectations usually go beyond just machining, which is why we take a great deal of pride in our high level of customer service and the broad array of ancillary services we offer. We strive to work closely with each customer to exceed their expectations in all areas.

Our Ancillary Services include but are not limited to warehousing of raw and finished materials for JIT delivery, production sawing, light assembly, heat treatment, various coatings and specialty packaging for drop shipments. We also specialize in manufacturing our own foundry tooling and conversion of expensive materials like steel forgings to more cost effective grey, ductile and austempered ductile iron castings.

We have put considerable effort in becoming an industry leader in machining ADI (austempered ductile iron). We regularly machine ADI to a hardness of about 500 brinell. This is possible largely due to the development of our own specialty tooling and coolant formulas.

Today’s highest level of performance. Advanced engineering techniques that shape the future of railroad technology. It’s no wonder Magnus is the #1 choice of Class 1 and short line railroads.

OUR CAPABILITIES

Precision Robotic Manufacturing

- Places and removes bearings

- Improves the accuracy of loading and handling

- Deburring (Removes Sharp Edges)

Over 130 Years of Innovation

- Advanced engineering techniques

- World-Class Quality and Performance

- Patented Designs

Higher Level Performance

- Centrifugal Horizontal Casting

- Strength and Durability

- Tighter Control of Critical Dimensions

Global Technical Support

- Repair shop audits

- Technical training

- Predictive testing recommendations

MAGNUS NEWS AND INFORMATION

Industry Exclusive Centrifugal Horizontal Casting

A Passion for Perfection

A Passion for Perfection